Comprehending the Removal Process in Black Granite Quarries

Comprehending the removal procedure in black granite quarries is critical for professionals in the rock sector. This process includes several stages, each calling for certain strategies and devices to ensure the effective extraction and processing of the granite.

Expedition and website assessment are the initial actions, where geologists analyze the land to figure out the top quality and quantity of the granite deposits. Quarrying and blowing up methods are after that employed to draw out the granite blocks from the quarry. Once drawn out, the blocks are moved and sorted based upon their dimension and top quality.

By comprehending the removal procedure, professionals can guarantee the responsible and sustainable sourcing of black granite, while also providing top quality items to meet the needs of the construction and design sectors. impala black granite quarry.

Exploration and Website Evaluation

Throughout the preliminary stages of the extraction procedure in black granite quarries, expedition and website assessment are performed to identify the usefulness and possibility of the quarry site. This action is essential as it helps in making informed decisions relating to the viability of the website for removal tasks.

Expedition includes performing a complete examination of the site to identify the visibility and top quality of black granite gets. Rock hounds and other professionals make use of different methods such as geological mapping, remote picking up, and drilling to collect information on the structural and geological qualities of the area. This information helps in estimating the amount and top quality of the granite down payments.

It includes reviewing the ecological, social, and financial facets of the quarry website. Economic elements, such as transportation facilities and market demand, are evaluated to establish the productivity of the quarry.

Quarrying and Blowing Up Strategies

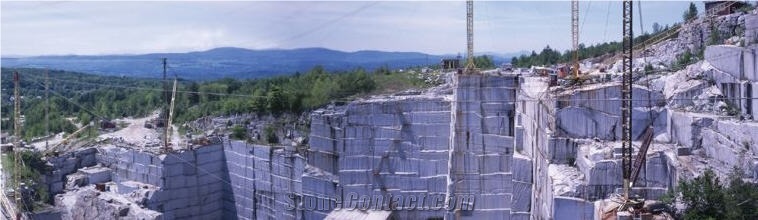

Quarrying and blowing up techniques play a pivotal duty in the extraction procedure of black granite quarries, guaranteeing regulated and efficient elimination of the rock. These techniques include using dynamites to damage the granite into manageable items that can be easily transported and processed.

Quarrying is the initial step in the procedure, where huge blocks of granite are removed from the planet's crust. The choice of quarrying approach depends upon different aspects such as the size and top quality of the deposit, as well as the preferred end item. Typical quarrying strategies consist of open-pit mining, underground mining, and directing.

Blowing up, on the various other hand, is the controlled use nitroglycerins to crack the granite and promote its removal. The major goal of blasting is to develop cracks and fissures in the granite, enabling much easier separation from the surrounding rock. This procedure needs careful planning and implementation to ensure the safety and security of workers and minimize ecological influences.

Transport and Type Of Granite Blocks

The reliable transport and specific sorting of granite blocks are crucial steps in the removal procedure of black granite quarries. As soon as the granite blocks have actually been extracted from the quarry using quarrying and blowing up strategies, they require to be moved to the processing facility or storage lawn for more processing or sale.

Transportation of granite obstructs needs cautious planning and control. The dimension and weight of the blocks can differ, so it is necessary to ensure that the lorries made use of for transport are ideal and can securely bring the load.

Upon arrival at the processing facility or storage lawn, the granite blocks are arranged based on their quality, size, and intended use. Arranging is a vital step as it enables effective handling and guarantees that the blocks fulfill the desired requirements. Competent employees meticulously check out each block, assessing its color, structure, and structural stability. Blocks that satisfy the needed requirements are reserved for additional processing, while those that do not fulfill the standards may be made use of for less demanding applications or disposed of.

Trimming and Shaping the Rock

Efficiently reducing and shaping the removed granite blocks is a crucial action in the extraction process of black granite quarries. As soon as the blocks have been delivered and sorted, they are ready to undertake the cutting and shaping procedure. This procedure involves using specialized equipment and devices to transform the raw blocks right into numerous shapes and sizes according to the particular needs of the task.

The initial step in cutting the blocks is to develop a collection of identical cuts along the desired dimensions. This is normally done using a diamond wire saw or a diamond chain saw, which have the ability to reduce with the challenging granite product. The blocks are after that further shaped and fine-tuned utilizing different cutting and shaping devices, such as diamond-tipped blades and grinding wheels.

Throughout the cutting and forming procedure, it is i thought about this necessary to guarantee precision and accuracy to attain the preferred measurements and finishes. Experienced drivers use their competence to meticulously steer the machinery and devices, making exact cuts and forming the blocks according to the specs given.

As soon as the cutting and forming procedure is complete, the granite blocks await further processing or to be made use of directly for building objectives. Efficient cutting and shaping of official source the rock not only makes certain the wanted quality and surface yet additionally makes the most of the usage of the extracted granite blocks, reducing waste and maximizing sources.

Polishing and Completing Processes

To accomplish the wanted smoothness and shiny look, black granite blocks go through meticulous sprucing up and completing processes. impala black granite quarry. After the cutting and shaping stages, the blocks go through numerous strategies to enhance their visual charm and draw out the natural charm of the stone

The initial step in the polishing and finishing process is grinding. This action not just enhances the appearance of the granite however likewise assists to seal the surface, making it extra resistant to spots and water damage.

As soon as the grinding and polishing stages are total, the blocks await the last finishing touches. This might involve applying a sealer or impregnator to further boost the recommended you read color and secure the surface. Furthermore, some black granite selections may undertake a process called flaming, which involves revealing the surface area to extreme heat to create a special distinctive finish.

Final Thought

Finally, the removal procedure in black granite quarries includes a number of phases, consisting of exploration and website assessment, quarrying and blowing up methods, transport and sorting of granite blocks, forming the stone and reducing, in addition to sprucing up and finishing procedures. This thorough procedure allows for the production of high-grade black granite items.

Quarrying and blasting techniques are then employed to draw out the granite blocks from the quarry.Quarrying is the first step in the process, where big blocks of granite are extracted from the earth's crust.Upon arrival at the handling center or storage space yard, the granite blocks are sorted based on their quality, size, and intended use.Effectively cutting and forming the extracted granite blocks is an essential action in the extraction procedure of black granite quarries. Additionally, some black granite varieties may undertake a process called flaming, which includes subjecting the surface to extreme heat to develop a special textured coating.